Job materials can be used to forecast procurement and supply chain management values that are based on the schedule. While these amounts will not drive the schedule, they can be used to model additional capital and other material requirements as well-based on activity. Since the materials are tied to the schedule, the forecasted requirements shift dynamically as the schedule changes.

From 2.14 onwards, the results of Job Material calculations within the schedule may now be accessed within the rest of the calculation using functions. This improvement enables dynamic response in cost and scheduling based upon available materials, specifically designed for the use case of water recycling. See How to Set Up a Dynamic Water Recycle Calculation.

Setup

To input and create the job material, go toManage Job Materialsunder theEnterprisemenu. The first time using Job Material, the screen will look as shown below. The first step is to create a Job Materials Set by clicking theAddbutton.

Click image to expand or minimize.

After creating the set, select the Capital Set to be used. Make sure this capital set matches the capital definitions being used in your project’s economic model if the material has a financial cost. You can incorporate up to 20 materials into a single Materials Set. A Materials Set is linked to an activity step, so if some of the 20 material types should not be modeled on the same activity step, create a separate Material Set for them.

Each material type must have the following settings filled out:

- Material Type: Used to specify the material number you would like the line to represent (1 – 20)

- Amount of Job Material: Function enabled, used to reference the amount of material required for a certain step in the process. E.g., X tons of sand are needed to frac one well.

- Cost: Function enabled, used for cost calculations related to the amount of material in the “Amount of Job Material” box.

- Capital Definition: The costs can be booked as a certain capital class that is part of the capital set referenced earlier, or “not booked as capital”. This can ensure capital costs are not double counted if there is already a separate formula for capital costs on the step.

- Spread over job duration: If this is left unselected, all of the material and cost will be used when the activity tied to the Job Materials set begins. If it is checked, the materials will be used over the duration of the activity.

- Comment: Since the material types can’t be named, the comment box should be used to specify the material for each line.

- After each box is completed, click save again and exit out of the Job Materials module.

Well Settings

You can specify Job materials in the Drilling Step rules or as an override within the well list. For ease of data management, it is recommended that the definition is specified in the Drilling Step rules wherever possible.

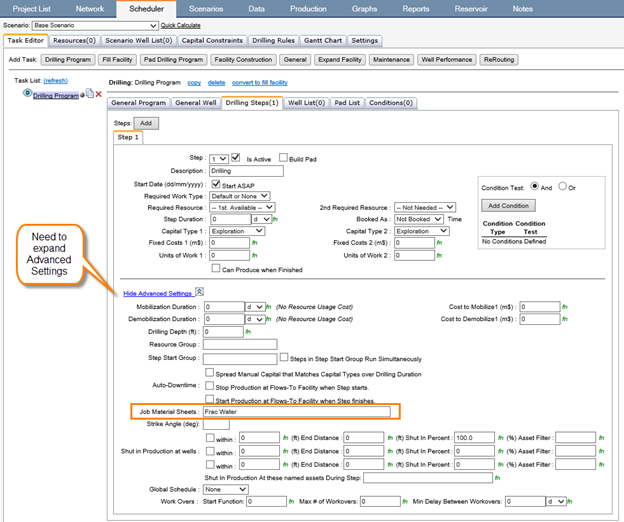

When specifying as part of the drilling step rules, for the particular activity you need to expand the advanced settings then specify the Job Materials to be used. Where multiple materials are used by a single step, you can specify them using comma separation.

Click image to expand or minimize.

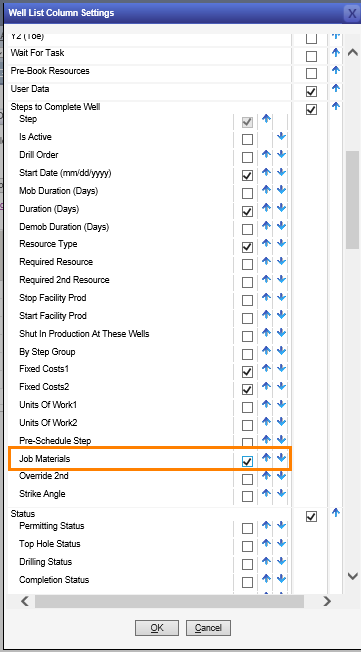

In the well list each job material set can be linked to an activity step. First make sure the Job Materials columns is visible in the well list.

Click image to expand or minimize.

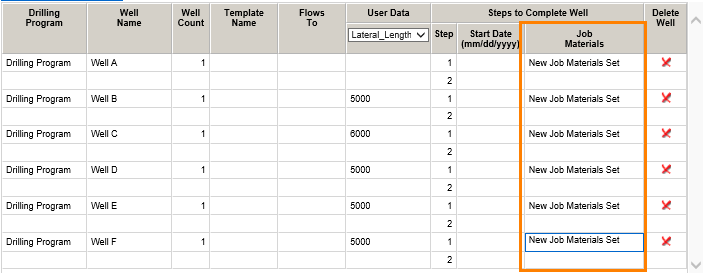

Fill in the job material set name into the well list column on the step that it relates to.

Click image to expand or minimize.

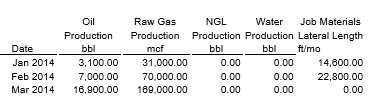

Reporting

After calculating, the forecasted values will roll up appropriately based on the wells flow path and the network hierarchy. A report must have Job Materials selected as the property in order to show the values. The results of the forecasted activity and corresponding job materials calculations will roll up and can be grouped as other similar reporting aspects.

Functions

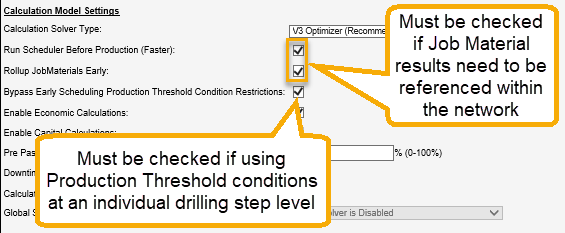

Two different types of functions are available from 2.14 onwards for the accessing of Job Material results mid-calculation to cover the evaluation of results within the network and whether a scheduled step should proceed. For both cases, some of the calculation model settings under Project Data must be adjusted. These checkboxes were introduced to ensure existing calculations could persist as is and clearly segment the use cases where reacting to Job Materials results were applicable.

Network Evaluation of Results:

Evaluation of results with the Network (included under Asset \ Production Results):

@JobMaterialsResults([Asset Name], JobMaterialType, JobMaterialProperty, [Index])

@JobMaterialsResultsDaily([Asset Name], JobMaterialType, JobMaterialProperty, [Index])

Where valid inputs for JobMaterialType would be MaterialType1, MaterialType2… and valid inputs for JobMaterialProperty are Amount and Cost e.g. @JobMaterialsResults('Water Tank', MaterialType1, Amount, @Monthstep()).

Schedule Evaluation of Results

The pre-evaluation of Job Materials within drilling step definition uses a different function as it occurs at an earlier time in the calculation prior to actually committing to the step proceeding and thereby a temporary number. This function is specifically designed to be used in conjunction with the Production Threshold condition type (included under Task \ Drilling Program Condition).

@TaskConditionJobMaterials([Job Material Type Name or Index]) – Evaluates the specified Job Materials Type assigned to the current calculation drilling entry associated with a production threshold condition e.g. @TaskConditionJobMaterials(0)